As we step into 2026, the landscape of nondestructive testing (NDT) is evolving, particularly in the realms of radiography and ultrasonic testing. This article aims to provide essential calibration tips that align with the latest standards, ensuring compliance and accuracy in testing processes. Readers will learn about the most recent updates in NDT standards, best practices for calibration, and the importance of maintaining high-quality equipment. The focus will be on how to navigate the complexities of calibration in radiography and ultrasonic testing, addressing common challenges and offering practical solutions.

In this guide, we will explore the latest radiography NDT standards, optimization techniques for ultrasonic testing calibration, the significance of ISO/IEC 17025 accreditation, preventative maintenance tips, and common calibration errors to avoid. By the end of this article, you will be equipped with the knowledge to enhance your NDT calibration practices effectively.

What Are the Latest Radiography NDT Standards for 2026?

The latest radiography NDT standards for 2026 reflect ongoing advancements in technology and methodology. These standards are designed to enhance the accuracy and reliability of radiographic testing, ensuring that results meet the stringent requirements of various industries. Compliance with these standards is crucial for maintaining the integrity of testing processes and ensuring safety in applications ranging from aerospace to construction.

How Does SIST EN ISO 32679:2026 Impact Radiography Calibration?

SIST EN ISO 32679:2026 is a forthcoming standard under development related to industrial radiographic film systems and their classification, but as of mid-2024, it has not been officially published or widely adopted. Therefore, its specific impact on radiography calibration practices remains to be confirmed. Current calibration practices continue to rely on established standards such as ISO 5579 and ISO 19232 series. Laboratories should monitor updates from ISO and national bodies for the official release and implementation guidance of ISO 32679.

What Are Key Compliance Requirements for Digital Radiography Systems?

Digital radiography systems must adhere to specific compliance requirements to ensure their effectiveness and safety. These requirements include regular calibration checks, adherence to quality control protocols, and the implementation of robust data management systems. Non-compliance can lead to inaccurate results, which may have serious implications in critical industries. Therefore, understanding and implementing these compliance criteria is essential for any organization utilizing digital radiography systems.

Understanding the historical development and varying requirements across different standard organizations is crucial for navigating digital radiography compliance.

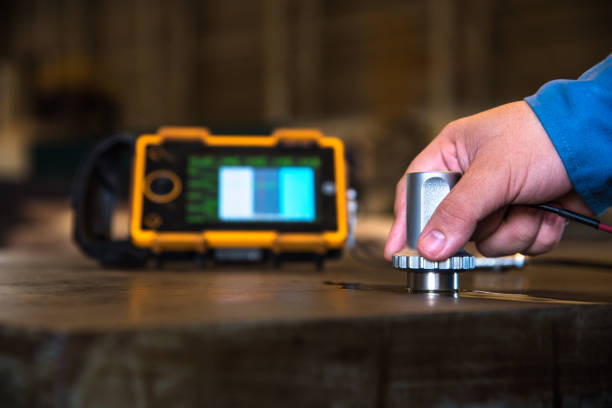

How Can You Optimize Ultrasonic Testing Calibration in 2026?

Optimizing ultrasonic testing calibration in 2026 involves adopting best practices that align with the latest industry standards. This includes utilizing advanced calibration techniques and ensuring that equipment is regularly maintained and calibrated to meet specific testing requirements. By focusing on these areas, organizations can enhance the accuracy and reliability of their ultrasonic testing processes.

What Are the Updated ISO 7963 and ISO 16946 Standards for UT?

ISO 7963:2018 specifies reference blocks for ultrasonic testing, and ISO 16946:2016 provides guidelines for ultrasonic testing of welds using phased array techniques. As of mid-2024, there are no published updates to these standards for 2026. These standards remain current and provide comprehensive guidelines for calibration and testing procedures. They emphasize the importance of using calibrated reference blocks and maintaining consistent testing conditions to ensure accurate results. Understanding these standards is vital for organizations aiming to comply with international requirements and improve their testing accuracy.

How to Properly Use Reference Blocks and Phased Array Techniques?

Proper use of reference blocks and phased array techniques is essential for effective ultrasonic testing. Reference blocks serve as benchmarks for calibrating equipment and verifying measurement accuracy. Phased array techniques, on the other hand, allow for more detailed inspections by utilizing multiple ultrasonic beams. To maximize the benefits of these techniques, technicians should follow established protocols and ensure that equipment is calibrated correctly before testing.

Why Is ISO/IEC 17025 Accreditation Crucial for NDT Calibration Labs?

ISO/IEC 17025 accreditation is a critical benchmark for NDT calibration laboratories, ensuring that they meet international standards for quality and competence. This accreditation signifies that a laboratory is capable of producing valid and reliable test results, which is essential for maintaining customer trust and compliance with regulatory requirements.

How Does Accreditation Ensure Calibration Precision and Reliability?

Accreditation under ISO/IEC 17025 ensures calibration precision and reliability by enforcing strict quality management systems and regular audits. Accredited laboratories must demonstrate their ability to produce accurate results consistently, which involves adhering to standardized procedures and maintaining well-documented records. This level of oversight not only enhances the credibility of the laboratory but also assures clients of the quality of the testing services provided.

What Is Newco Inc.'s Role in Maintaining ISO 17025 Standards?

Newco, Inc. plays a pivotal role in maintaining ISO 17025 standards through its commitment to quality and precision in NDT calibration services. As a leading nondestructive testing equipment distributor, Newco, Inc. ensures that its calibration lab is ISO/IEC 17025:2017 accredited, providing clients with confidence in the accuracy and reliability of their testing equipment. This commitment to excellence is reflected in the comprehensive range of calibration services offered, including preventative maintenance and equipment repair.

What Are Essential Preventative Maintenance Tips for NDT Equipment?

Preventative maintenance is crucial for ensuring the longevity and reliability of NDT equipment. Regular maintenance not only extends the lifespan of the equipment but also helps prevent costly breakdowns and inaccuracies in testing results. Implementing a structured maintenance schedule can significantly enhance the performance of NDT tools.

How Does Regular Maintenance Extend Equipment Lifespan?

Regular maintenance extends the lifespan of NDT equipment by addressing wear and tear before it leads to significant issues. This includes routine inspections, cleaning, and calibration checks. By adhering to a proactive maintenance schedule, organizations can ensure that their equipment operates at peak performance, reducing the likelihood of unexpected failures and costly repairs.

What Are Common Calibration Errors and How to Avoid Them?

Common calibration errors can significantly impact the accuracy of NDT testing results. These errors may arise from improper calibration techniques, equipment malfunctions, or failure to adhere to established protocols. To avoid these pitfalls, technicians should be trained in proper calibration methods, regularly check equipment functionality, and maintain detailed records of calibration activities. By implementing these practices, organizations can minimize errors and enhance the reliability of their testing processes.

- Calibration Checks: Performed monthly to ensure accurate measurements

- Equipment Cleaning: Completed weekly to prevent contamination and reduce wear

- Functional Testing: Conducted quarterly to verify proper operation and integrity

In conclusion, adhering to the latest NDT calibration standards and implementing best practices is essential for ensuring compliance and accuracy in radiography and ultrasonic testing. By focusing on preventative maintenance and understanding the implications of ISO/IEC 17025 accreditation, organizations can enhance their testing processes and deliver reliable results.