Global Gray Cast Iron Rod Market to Reach USD 788.2 Million by 2035 as Automotive, Construction, and Precision Casting Drive Demand

Driven by automotive manufacturing, industrial modernization, and advanced casting technologies, gray cast iron rod adoption accelerates across machinery and infrastructure sectors.

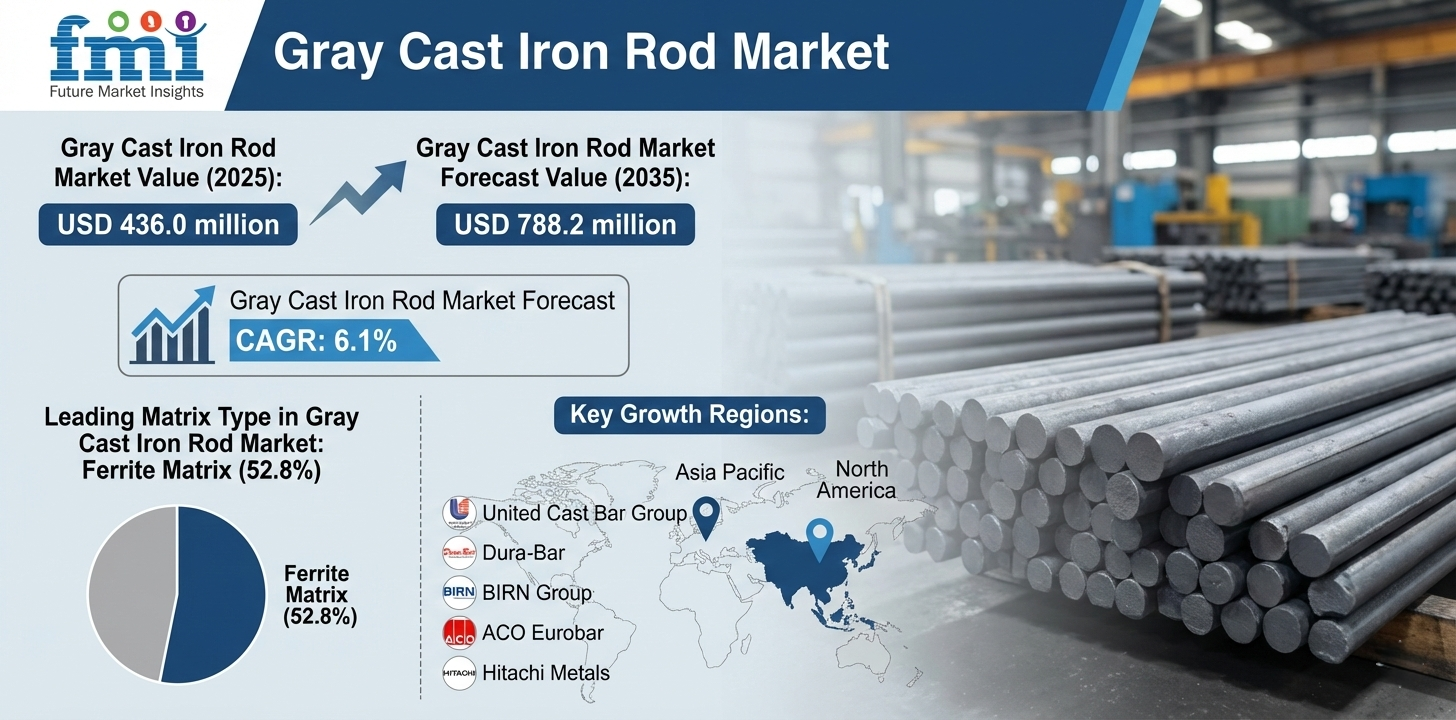

NEWARK, DELAWARE / ACCESS Newswire / February 11, 2026 / The global gray cast iron rod market is entering a phase of sustained expansion, projected to grow from USD 436.0 million in 2025 to USD 788.2 million by 2035, reflecting a compound annual growth rate (CAGR) of 6.1%. According to industry outlooks, rising demand from automotive manufacturing, construction, machinery production, and industrial equipment applications is reinforcing gray cast iron rods' role as a critical material for precision-engineered components.

Gray cast iron rods continue to gain traction due to their excellent machinability, wear resistance, vibration damping, and cost-effectiveness, making them a preferred solution in sectors focused on operational reliability and production efficiency. China and India are emerging as high-growth markets, while the United States and Germany remain major consumption hubs supported by mature manufacturing ecosystems and advanced casting infrastructure.

As industries increasingly prioritize high-performance materials and automated production systems, gray cast iron rods remain central to innovation across automotive components, industrial machinery, and construction materials.

Ferrite Matrix and Automotive Applications Form the Market Backbone

Ferrite matrix gray cast iron rods dominate the global market, accounting for approximately 52.8% of total demand. These rods are widely used for their superior machinability, dimensional stability, and proven reliability across diverse manufacturing environments. Ferrite matrix compositions enable consistent performance in high-volume production through advanced casting techniques and precision machining workflows.

The automotive industry represents the largest application segment, contributing nearly 41.7% of global gray cast iron rod demand. Gray cast iron rods are extensively utilized in engine blocks, cylinder heads, housings, and structural components, where durability and thermal stability are essential. Continuous growth in global vehicle production and increasing adoption of precision casting technologies continue to support stable consumption from automotive manufacturers.

Other key applications include construction and infrastructure, machinery manufacturing, industrial equipment, metal casting, and consumer goods, underscoring gray cast iron rods' versatility across performance-driven industries.

"Gray cast iron rods remain indispensable where machinability, durability, and dimensional consistency are essential," notes industry analysis. "From automotive engines to industrial machinery, these materials enable reliable production outcomes and long-term operational efficiency."

Industrial Manufacturing and Precision Casting Drive Consistent Adoption

Global demand for gray cast iron rods is strengthening as industries respond to manufacturing modernization, component optimization, and efficiency requirements:

Automotive Growth: Increasing use in engine and structural components supports performance reliability and cost-efficient production.

Construction Expansion: Reinforcing bars, pipes, and fittings benefit from gray cast iron's strength and durability.

Machinery Manufacturing: Frames, housings, and supports rely on excellent machinability and mechanical stability.

Metal Casting Applications: Gray cast iron remains a preferred material for diverse industrial castings.

Consumer Goods: Home appliances and cookware utilize gray cast iron for thermal conductivity and deformation resistance.

However, competition from alternative metals, casting process complexity, and material cost pressures present ongoing challenges. In response, manufacturers are investing in automated casting systems, quality control integration, and advanced matrix compositions to improve consistency, sustainability, and cost competitiveness.

Regional Growth Engines: China Leads, India Accelerates, Europe and the U.S. Anchor Demand

The gray cast iron rod market is expanding globally, led by Asia Pacific and supported by steady demand in North America and Europe.

Country | Projected CAGR (2025-2035) | Primary Growth Drivers |

China | 8.2% | Automotive manufacturing, industrial expansion, precision casting |

India | 7.6% | Infrastructure development, machinery production, manufacturing investment |

Germany | 7.0% | Advanced casting technology, automotive components |

Brazil | 6.4% | Automotive growth, industrial production |

United States | 5.8% | Manufacturing automation, component optimization |

United Kingdom | 5.2% | Material reliability, mature industrial markets |

Japan | 4.6% | Precision manufacturing, quality-driven applications |

China leads global growth through its expanding automotive sector and strong manufacturing base, while India demonstrates rapid momentum fueled by infrastructure development and industrial investment. Germany maintains leadership in technical excellence, and the United States continues to anchor demand across automotive, machinery, and industrial applications.

European markets benefit from established manufacturing standards, while Japan sustains steady growth through precision-focused production systems.

Sustainability and Advanced Manufacturing Shape Market Evolution

Despite favorable demand trends, the gray cast iron rod industry faces increasing pressure to improve production efficiency and environmental performance. Manufacturers are responding through innovation initiatives, including:

Integration of automated casting and inspection systems

Development of advanced matrix compositions for enhanced mechanical properties

Adoption of digital quality control and dimensional monitoring

Investment in efficient melting and forming technologies

Expansion of application-specific rod varieties for premium manufacturing outcomes

Long-term scalability depends on balancing precision engineering with production efficiency while meeting evolving performance requirements across automotive, construction, and industrial markets.

Competitive Landscape and Market Dynamics

The global gray cast iron rod market remains moderately consolidated, with leading players benefiting from casting expertise, integrated manufacturing operations, and established distribution networks. Competition increasingly centers on product consistency, technological innovation, and application-specific solutions rather than volume alone.

Major producers continue to expand capabilities to support growing demand from automotive and industrial sectors while advancing automated casting workflows and premium material engineering. Companies that successfully integrate quality assurance systems and advanced manufacturing practices are expected to maintain a competitive edge.

Key Players in the Gray Cast Iron Rod Market

United Cast Bar Group

Dura-Bar

BIRN Group

ACO Eurobar

Hitachi Metals

KOGI Corporation

Encore Metals

Nippon Chuzo

Hengong Precision Equipment

Jiangsu Hualong Precision Intelligent Manufacturing

Henan Guotai Profile Technology

Wuan City Qichang Casting

Continental Cast Iron

These companies compete through casting innovation, matrix optimization, and expansion into high-growth regions, reinforcing gray cast iron rods' strategic importance within the global materials and manufacturing ecosystem.

For an in-depth analysis of evolving formulation trends and to access the complete strategic outlook for the Gray Cast Iron Rod Market through 2035, visit the official report page at: https://www.futuremarketinsights.com/reports/gray-cast-iron-rod-market

Related Reports:

Gray Cast Iron Profile Market: https://www.futuremarketinsights.com/reports/gray-cast-iron-profile-market

Demand for Gray Cast Iron Profile in UK: https://www.futuremarketinsights.com/reports/demand-for-gray-cast-iron-profile-in-uk

Iron and Steel Casting Market: https://www.futuremarketinsights.com/reports/iron-and-steel-casting-market

Environmental-Product-Declaration-Ready Low-Carbon PVC Compounds Market: https://www.futuremarketinsights.com/reports/environmental-product-declaration-ready-low-carbon-pvc-compounds-market

Iron Oxides Market: https://www.futuremarketinsights.com/reports/iron-oxides-market

About Future Market Insights (FMI)

Future Market Insights (FMI) is a leading provider of market intelligence and consulting services, serving clients in over 150 countries. Headquartered in Delaware, USA, with a global delivery center in India and offices in the UK and UAE, FMI delivers actionable insights to businesses across industries including automotive, technology, consumer products, manufacturing, energy, and chemicals.

An ESOMAR-certified research organization, FMI provides custom and syndicated market reports and consulting services, supporting both Fortune 1,000 companies and SMEs. Its team of 300+ experienced analysts ensures credible, data-driven insights to help clients navigate global markets and identify growth opportunities.

For Press & Corporate Inquiries

Rahul Singh

AVP - Marketing and Growth Strategy

Future Market Insights, Inc.

+91 8600020075

For Sales - [email protected]

For Media - [email protected]

For web - https://www.futuremarketinsights.com/

SOURCE: Future Market Insights, Inc.

Information contained on this page is provided by an independent third-party content provider. XPRMedia and this Site make no warranties or representations in connection therewith. If you are affiliated with this page and would like it removed please contact [email protected]